Know about EPS

How it's made

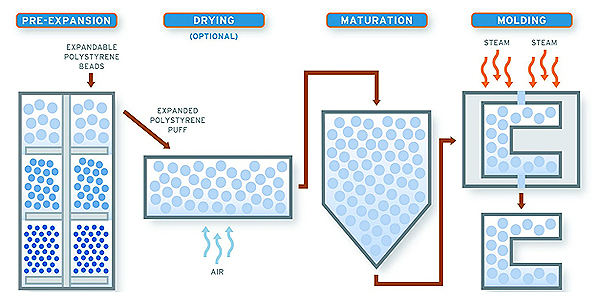

E.P.S. (Expandable Poly Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS.

These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups.

Youtube Video gallery

What are the properties?

Main Component: 92%~ 96% polystrene

Appearance: Colorlessly transparent or opaque tiny beads

Density: about 1.04

Bulk density: About 0.6

| Beed Size (mm) | Description | Product Density (Kg/Cu.m) |

| 1.2-1.6 | Heavy duty block sheet and lightweight molding | 11.8 ~ 12.5 |

| 0.8-1.2 | Middle density applications | 12.5 ~ 15.4 |

| 0.6-0.9 | High density application | 13.3 ~ 16.7 |

How do we classify EPS?

- Regular Grades: high expansion, medium grade, fast cycling, colorful beads

- Flame Retardant:high ratio

Expansion

Providing high expansion ratio, suitable for producing low density blocks, insulation boards and packaging products;

Grade

Providing medium expansion ratio, suitable for producing general packaging products and medium density blocks;

Cycling

Providing medium expansion ratio with short molding time, suitable for molded products for shape molding machine;

Flamability

Providing medium and high expansion ratio, suitable for low density building insulation panels and other products;

Pentane Level

Providing medium and low expansion ratio, suitable for high density blocks and framing parts.

What are the abundant applications?

- Packaging: (Vegetable and fruit box, Fish box, Electronics packaging)

- New Building Material: (Sandwich panel, 3D panel, Brick insert, Insulated Concrete Forms(ICF))

- Plastic Foam Flotation: (Float)

- Decorating Material: (Cornices, Ceiling tiles, Articles in arts and crafts for advertisement and decoration)

- Full Mould Casting;

- Protecting material: (Anti-freeze pad to cushion foundations of roads and railways in high cold region)

- Filter material: (Applicable in medium and small scaled water supply system)

- Other applications: (Applicable in seeding nurseries for hydroponics; Mixed with clay and cement to manufacture lightweight wall tiles and cement castings; As filling material for pillow….)

Regular Grades:

- P. S. (Expandable Poly Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts

- Of pentane gas dissolved into the polystyrene base material during production.

- The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS.

- These cells occupy approximately 40 times the volume of the original polystyrene bead.

- The EPS beads are then molded into appropriate forms suited to their application.

- Products made from foamed polystyrene are nearly ubiquitous, for example packing materials,

- Insulation, and foam drink cups.

Fire Grade:

EPS Fire Retardant grade is used for production EPS blocks, insulation construction material for panel applications, housing, and constructions. Heat preservation and insulation materials. With high strength, fast forming, high foaming and oxygen index. Oxygen index is above 30.